Quality

Quality Assurance and Testing

We have always been genuinely committed to meeting and exceeding our customer’s expectations in terms of design, manufacture and delivery of products. We have a great tradition of forging strong and enduring relationships with customers who trust our skilled workmanship as well as the consistently high standards of service we strive to achieve. With a proven track record of meeting demanding schedules and delivering to contract deadlines, we have become the chosen manufacturing partner of a number of Ireland’s key companies in the engineering, water/wastewater treatment and chemical sectors. At Alpha Tanks we are customer focused with positive leadership, a systematic approach to management and with a commitment to continuous improvement.

Quality Management System

Our Quality Management System is certified to ISO 9001:2015 for the design, fabrication and manufacture of tanks, vessels and bespoke engineering fabrications. Detailed handover documentation packs are provided where required, each specifically tailored to meet customer and project requirements. ISO Certificate

Design Codes and Standards

We supply tanks and vessels designed, manufactured, inspected, tested and certified to the following codes and standards:

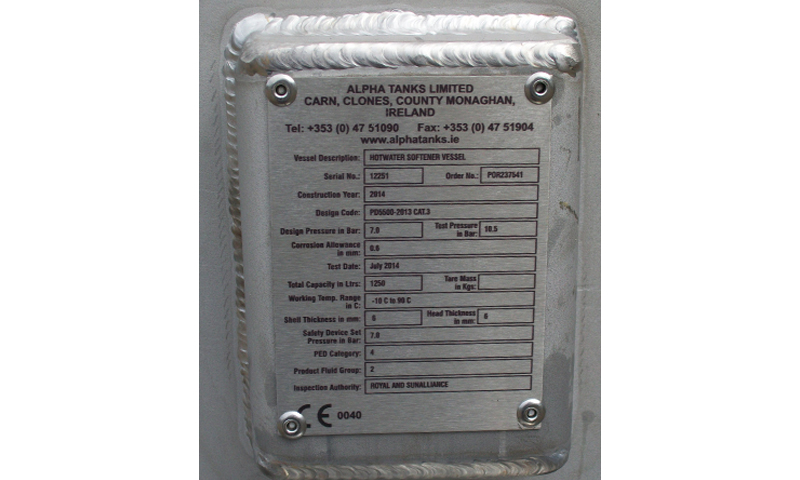

• The Pressure Equipment Directive 2014/68/EU (the PED)

• PD5500 construction category 1, 2 or 3

• ASME VIII Div. 1 (non code stamped)

• BS EN 13445

• BS EN 12079/DNV 2.7-1

• BS EN 12285-1 & -2 (horizontal storage tanks, steel)

• BS 799-5 (oil storage tanks, steel)

• OFS T200 (oil storage tanks, steel)

Welder Qualifications

Our team of skilled and experienced welders are certified by Royal and Sun Alliance Engineering, TUV UK and Lloyds Register to BS EN ISO 9606, BS EN ISO 15614 and ASME IX for MAG, TIG and Plasma TIG processes. Welding procedures and qualifications are held for both carbon and stainless steels.

Product Testing

We carry out hydrostatic testing on vessels in accordance with specified design codes and/or customer requirements. These pressure tests are normally independently witnessed by a notified body. Other tests such as leak (air and water) and vacuum testing can also be carried out on site. We operate a fully licensed industrial radiography test bay on site. An in-house radiographer can inspect welds for defects and integrity. Weld repairs can be undertaken where required. Other NDT processes such as Magnetic Particle Inspection (MPI) and Dye Penetrant Testing (DPT) can also be supplied by approved sub-contractors.

CE Marking of Pressure Vessels

Pressure vessels are constructed to either PD5500 or ASME VIII Div. 1 and can be CE marked in accordance with the Pressure Equipment Directive (the PED) for categories I, II, III & IV.

CE Marking of Steel Structures

We are certified to CE mark fabricated steel structures to EN 1090, up to and including Execution Class 2 (EXC2). This allows us to fabricate the vast majority of steel structures. Since July 1st 2014, under the Construction Products Regulations (CPR), it has been a legal requirement that fabricated structural steelwork delivered to construction sites must be CE certified. The European Standard for the CE marking of structural steelwork is EN1090-1:2009 + A1:2011. In order to be able to CE mark our steelwork fabrications, a certified Factory Production Control (FPC) system and a documented Welding Quality Management System (WQMS) must be in place.